Most important, in a practical sense, would be the construction of factories that could make use of the special properties of space — high and low temperatures, hard radiation. Unlimited vacuum, zero gravity — to manufacture objects that could be difficult or impossible to manufacture on Earth, so that the world's technology might be totally transformed. --- Isaac Asimov (The Stare)

You've probably seen these types of videos where some guy levitates a scrap of foil between two electromagnets.

What may be new is any practical use for this technology. On the ISS, there are two devices that use magnetic forces for amazing research into the properties of metals and metal alloys.

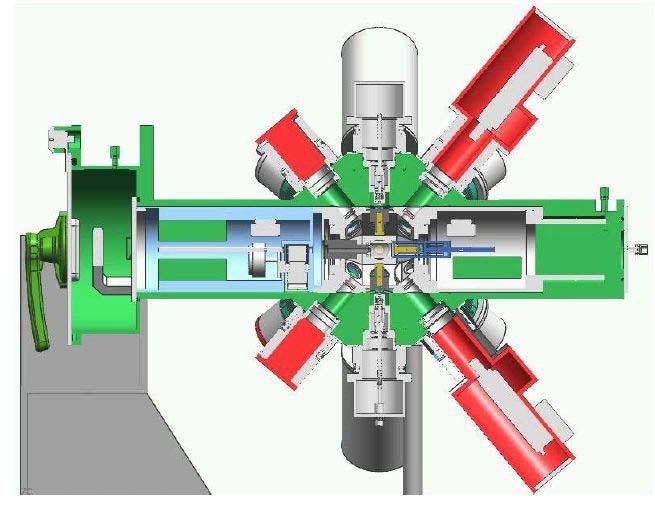

JAXA provided the Electrostatic Levitation Furnace (ELF) which has a setup of four electromagnets (shown below in red), with a laser heating apparatus capable of heating a sample to 2,000“C in a few seconds.

JAXA's Electrostatic Levitation Furnace (ELF).1

JAXA's Electrostatic Levitation Furnace (ELF).1

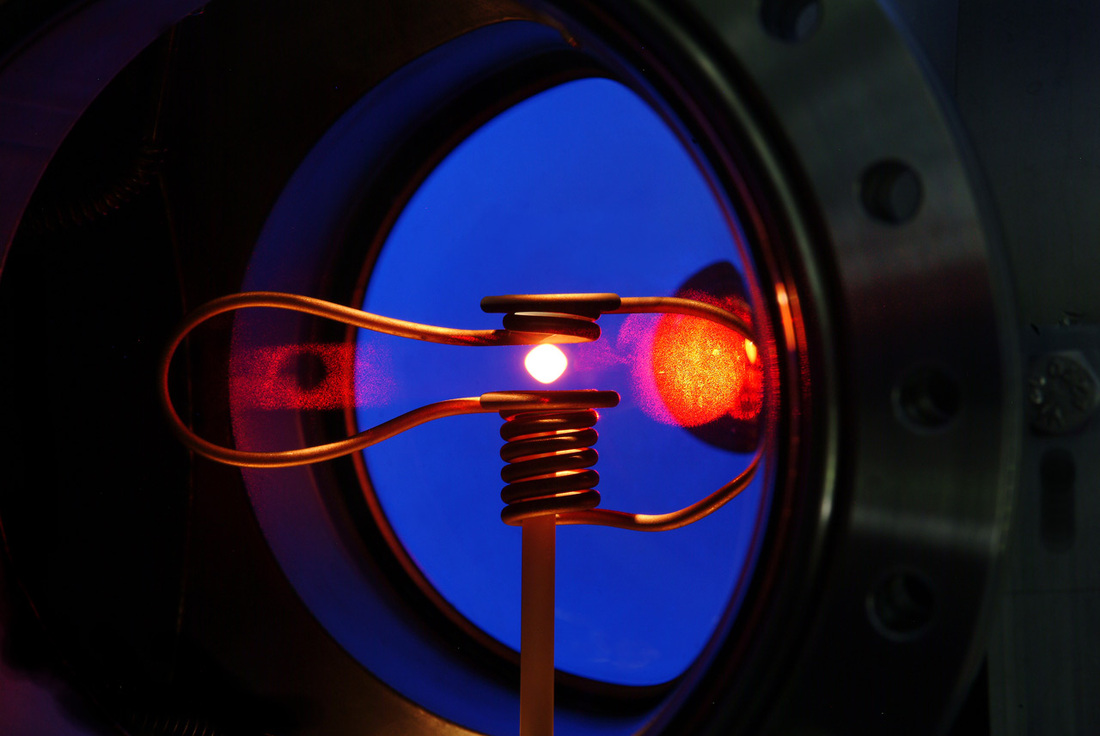

The ESA's version is called the Electromagnetic Levitator and uses the same principles, but heats the materials with magnetic fields instead of a laser.2

Heated Sample Droplet in Electromagnetic Levitator – Photo: ESA/DLR

Heated Sample Droplet in Electromagnetic Levitator – Photo: ESA/DLR

Read more about the importance of [Manufacturing in Space]().

The major benefits of this furnace come from the "special properties of space": the researcher's choice of atmosphere, including hard vacuum; and microgravity. On Earth, choosing the atmosphere the reaction occurs in is difficult, but in space, much easier; even the choice of no atmosphere becomes an option! This research is revealing that gravity plays more of a role in the metallurgic results than previously imagined. By removing gravity, we get a better understanding what is really happening.

A few years ago, some scientists 3

used this levitation equipment to explore the properties of "metal glass", a kind of alloy that cools without crystallizing.

Without the fault lines crystallization produces, the material's properties become extremely interesting, with

superior wear resistance,

large elastic strain limits, and

high yield strengths due, in part, to extreme hardness.

Imagine a metal as bendable as plastic that also snaps back into shape reliably over long periods of use.

LiquidMetal Technologies Inc. uses an alloy called Vit105 in their manufacturing processes on Earth.

Samples of Vit105 were heated in the electrostatic levitation furnace on the ISS and then allowed to cool. A camera captured the cooling action at 30 frames per second until the material cooled to 700ºC. Later analysis showed the material formed spheres only 25 μm away from being a perfect sphere, the equivalent to the ABMA ball grade 1000. Since the energy required to move things like vehicles often depends directly on how smoothly the parts interact, more prefect bearings made in space could significantly improve energy efficiency here on earth.

-

Electrostatic Levitation Furnace – Spaceflight101 – International Space Station. (n.d.). Spaceflight 101. Retrieved October 14, 2022, from https://spaceflight101.com/iss/electrostatic-levitation-furnace/ ↩

-

Electromagnetic Levitator – Spaceflight101 – International Space Station. (n.d.). Spaceflight 101. Retrieved October 14, 2022, from https://spaceflight101.com/iss/electromagnetic-levitator/ ↩

-

Mohr, M., Wunderlich, R. K., Hofmann, D. C., & Fecht, H.-J. (2019). Thermophysical properties of liquid Zr52.5Cu17.9Ni14.6Al10Ti5—Prospects for bulk metallic glass manufacturing in space. Npj Microgravity, 5(1), 24. https://doi.org/10.1038/s41526-019-0084-1 ↩